OUR SERVICE

we're here to make your Place Fullproof

Complete client satisfaction

At Amma Waterproofing, our commitment to complete client satisfaction is the foundation of everything we do. We understand that every project is unique, and our goal is to exceed your expectations, delivering not just results but a positive and seamless experience from start to finish.

Wide connectivity

Connectivity is at the heart of providing exceptional customer service and delivering efficient solutions. Wide connectivity enables us to stay in touch with our clients, partners, and stakeholders across multiple platforms, ensuring that you have the support you need whenever and wherever you need it.

Ethical business policies

Ethical business practices are fundamental to our success and the foundation of long-term relationships with our clients, employees, and the community. We are dedicated to upholding the highest standards of integrity, transparency, and responsibility in everything we do.

We listen,We understand, We provide Solution

The key to successful partnerships lies in truly understanding our clients’ needs. Our approach is simple: We Listen, We Understand, We Provide Solutions. Every step of our process is designed to ensure that you receive personalized, thoughtful service that addresses your unique challenges and delivers meaningful results.

Live In Touch With Our Customers

The key to exceptional service and success is maintaining strong, open communication with our clients. Our goal is to be accessible, responsive, and engaged, ensuring that your experience with us is seamless, personal, and always a step above your expectations.

A great experience with Happy clients

Nothing brings us more satisfaction than seeing our clients happy and thriving. We believe that a great experience is the foundation of lasting relationships, and we are dedicated to providing you with just that—a seamless, enjoyable experience that leads to happy clients who trust us for their future needs.

Transparent dealings

Transparency is the cornerstone of building strong, trustworthy relationships with our clients. Our commitment to transparent dealings ensures that you are always informed, confident, and satisfied with the services we provide.

Expertise in waterproofing

Wwe have years of experience and specialized knowledge in providing high-quality waterproofing solutions for homes, businesses, and industrial properties. Whether you're looking to protect your foundation, roof, or walls, our expertise in waterproofing ensures that your property stays safe, dry, and secure against the elements.

we're here to make yourPlace Fullproof

OUR PRODUCTS & SERVICES

OUR PRODUCTS & SERVICES

Ceiling Waterproofing

Water leakage from ceilings can cause severe damage, including mold growth, weakened structures, and aesthetic deterioration. Our ceiling waterproofing services provide long-term protection against water seepage, ensuring a safe and dry indoor environment.

Step 1: Identify the Source of Water Leakage

Step 2: Surface Preparation

Step 3: Apply Waterproofing Coating

Step 4: Install Protective Ceiling Materials (Optional)

Step 5: Regular Maintenance & Inspection

Cementitious Waterproofing

Cementitious waterproofing is a construction method used to protect surfaces from water damage. This type of waterproofing involves the application of a cement-based mixture to a surface, concrete, masonry, or brick to prevent water from entering the surface.

Swimmingpool Waterproofing

Waterproofing a swimming pool is essential to prevent leaks, structural damage, and water loss. Proper waterproofing ensures the longevity of the pool and enhances its durability against hydrostatic pressure and chemical exposure.

Without proper waterproofing, pools can suffer from:

Cracks and leaks due to water seepage.

Structural weakening from continuous water exposure.

Mold and algae growth caused by moisture penetration.

Increased maintenance costs due to water loss and repairs.

Roof & Slab Waterproofing

Waterproofing your roof and slab is essential to prevent water seepage, structural damage, and mold growth. Proper waterproofing ensures durability, reduces maintenance costs, and protects the structure from weather-related damage.

Why is Roof & Slab Waterproofing Important?

Prevents leaks and seepage that can weaken the structure.

Protects reinforced concrete from corrosion.

Increases building lifespan by reducing wear and tear.

Enhances thermal insulation, reducing temperature fluctuations.

Sump Waterproofing

Sump waterproofing is essential to protect basements and underground structures from water infiltration, preventing flooding, mold growth, and structural damage. This process ensures that sump pits and surrounding areas remain dry and functional.

Step 1: Inspect the Sump Pit & Drainage System

Step 2: Repair Cracks & Seal Joints

Step 3: Apply Waterproof Coatings

Step 4: Install a Sump Liner & Drainage System

Step 5: Maintain & Monitor the Sump System

Terrace Waterproofing

Terrace waterproofing is a process that protects a terrace from water damage by applying a waterproof coating or solution. It's important to waterproof a terrace to prevent water damage and ensure the structure's stability. Water damage can lead to mold growth, which weakens the structure's foundation and may cause it to collapse.

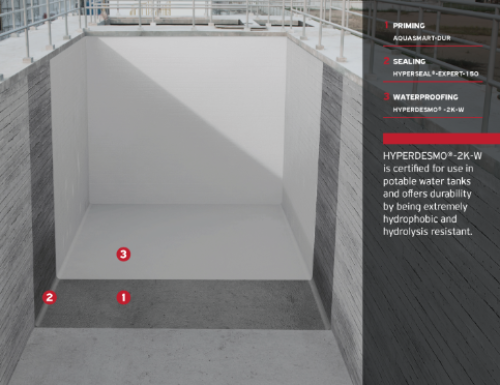

Tank Waterproofing

Tank waterproofing is a process that involves applying a sealant or coating to a water tank to prevent leaks and extend its life. It's important because water tanks are constantly exposed to water and can be damaged by

Cracks and porous materials

Adjoining walls and surfaces

The foundation

Contamination of stored water

Leakage Solution

- Waterproofing products: These chemicals can be applied to surfaces like roofs, walls, and balconies to create a watertight barrier.

- Sealants and patching materials: These can provide temporary relief, but they often don't address the root cause of the problem.

- Epoxy putty: This can be used to fix leaky pipes.

- Fiberglass tape: This can be used as a temporary seal for leaks.

- Self-fusing silicone tape: This can be used as a temporary fix for low pressure lines.

- Water management and drainage: This can be a solution to leakage problems.

- Coatings, sealers, reactants, and sheet liners: These can be used to solve leakage problems.

- Electro-osmotic pulse (EOP) technology: This can be used to solve leakage problems.

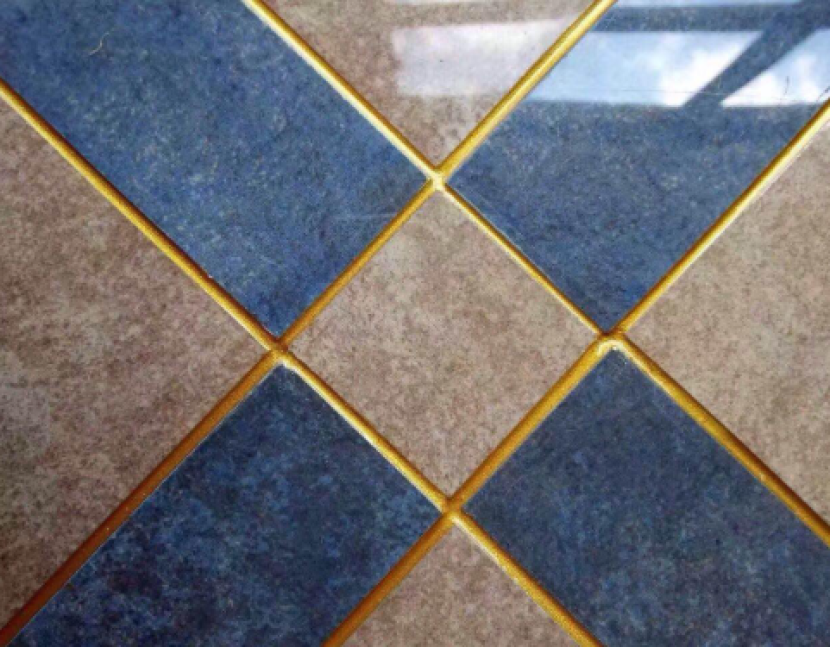

Epoxy Tile Joint Filling

Epoxy tile joint filler is a grouting material made from epoxy resin and hardener that's used to fill gaps and joints between tiles. It's a popular choice for bathrooms and other areas with high humidity because of its durability, water resistance, and stain resistance.

Here are some of the benefits of epoxy tile joint filler:

- Durable: Epoxy tile joint fillers are non-shrinking and won't break or leave gaps between tiles.

- Non-porous: Epoxy tile joint fillers don't absorb moisture, which prevents bacterial growth.

- Chemical-resistant: Epoxy tile grouts are easy to clean.

- Crack-resistant: Epoxy grout doesn't crack on the surface like cement grout.

- Elastic: Epoxy grout won't crumble or crack like traditional grouts when exposed to moisture.

To apply epoxy tile joint filler, you can:

- Prepare the surface so it's clean, dry, and loadbearing.

- Mix the resin and hardener together in the correct ratio.

- Apply the grout to the joints using an epoxy grout board.

- Remove excess grout.

- Clean immediately with a hydro sponge and warm water.

Epoxy Grouting

Epoxy grout is a synthetic resin and hardener mixture that's used to fill gaps between tiles or to stabilize the void between concrete and steel:

Properties

Epoxy grout is durable, water-resistant, and stain-resistant. It's also non-porous, which makes it resistant to mold, mildew, and stains. Epoxy grout is available in a variety of colors.

Uses

Epoxy grout is commonly used in industrial applications, such as chemical industries, laboratories, and food industries. It can also be used to grout tiles, mosaics, ceramic tiles, and other natural stones.

Benefits

Epoxy grout is a high-performance solution that can protect concrete surfaces from wear and tear. It's also easy to clean and maintain.

Safety

When working with epoxy grout, you should wear suitable protective clothing, gloves, and eyes/face protection. You should also wash your skin immediately with clean water if it comes into contact with epoxy grout.

Shelf life

Epoxy grout has a shelf life of 24 months when stored in a dry place.

Epoxy Flooring

Epoxy flooring is a durable, customizable, and cost-effective flooring option that's made from a combination of epoxy resin and a hardener:

Composition

Epoxy is a synthetic resin that's made from a combination of epoxy resins and hardeners. When mixed together, the two components undergo a chemical reaction that creates a rigid, durable, and impermeable plastic material.

Application

Epoxy flooring is typically applied as a liquid to concrete, metal, or wood surfaces. It can be applied in multiple layers that are troweled, coated, or poured.

Benefits

Epoxy flooring is resistant and durable, and it can be used in a variety of settings, from homes to industrial spaces. It's also cost-effective and low maintenance.

Maintenance

Epoxy flooring can be cleaned with water, a mop, and sometimes a mild soap. It's best to use a non-alkaline cleanser to avoid stripping the coating.

Installation

Epoxy flooring can be installed without removing the existing flooring, as long as the new epoxy can bond to the existing surface. It's best to install epoxy flooring at temperatures between 65 and 85°F

External & Internal Wall Crack Filling

Wall crack filling is a waterproofing technique that involves applying a material to fill cracks in walls and floors to extend the life of the structure. The right material to use depends on the type of crack:

- Vertical cracks: Use epoxy or polyurethane-based fillers

- Horizontal cracks: Use crack stitching techniques or carbon fiber reinforcement

- Diagonal cracks: Use flexible sealants or mortars

Here are some products and tips for wall crack filling:

Cracksil

A polymeric, modified powder material that can fill cracks up to 6 mm wide. It's non-shrinking, water resistant, and can be used as a surface leveler before painting.

WeatherTuff

A cementitious acrylic base sealer powder that's non-shrinking and free flowing. It can be applied to walls and RCC slabs.

Surface preparation

Clean the cracked area with a wire brush or scraper to remove loose debris, paint, or other contaminants.

Drywall

For small cracks in drywall, you can use a joint compound. Cut a V-notch along the crack, apply the compound, and let it dry for at least 24 hours. Then, sand and paint over the area.

Cracks in walls can be caused by a number of things, including foundation issues, deterioration, and age. Addressing foundation problems early can prevent structural damage.